Revolutionize Your Woodworking with Automatic Edge Banding Machine,Industry News

Are you tired of spending long hours manually edging your woodwork projects? It's time to consider investing in an Automatic Edge Banding Machine. An Automatic Edge Banding Machine is an automated device that simplifies edge banding and offers superior quality finishes. With this machine, you can save up on time, effort, and labor costs. In this blog post, we will delve deeper into the workings of an Automatic Edge Banding Machine, its advantages, and how it can revolutionize your woodworking business.

Advantages of Automatic Edge Banding Machine

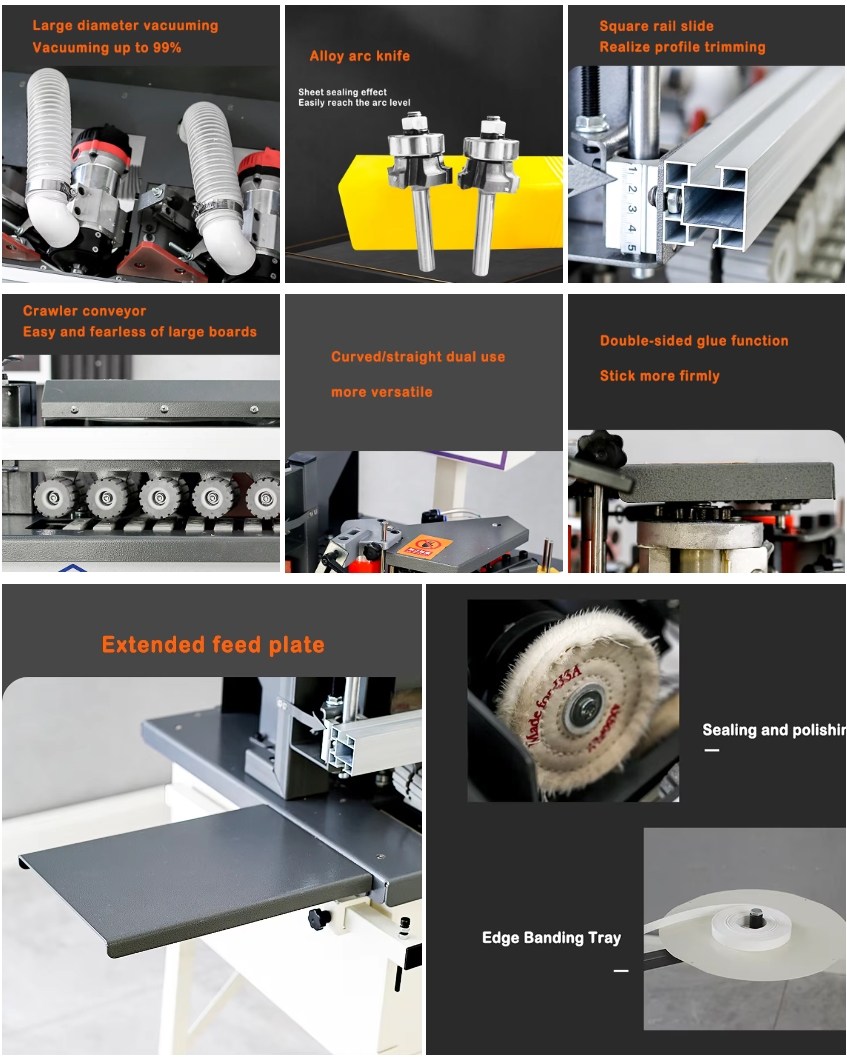

The Automatic Edge Banding Machine offers a range of advantages that make it an essential tool for woodworkers. One of the critical benefits is that it offers automated cutting, gluing, and trimming of edge bands, which means that you do not need to do these tasks manually. This machine also comes with a pre-milling unit that smoothes the surface, ensuring that the band adheres securely and precisely.

Another advantage of the Automatic Edge Banding Machine is that it offers consistent quality finishes. With a manual edging process, the quality of the finish depends on the skill level of the operator. However, with the Automatic Edge Banding Machine, the finish quality is consistent and of high quality, regardless of the operator. The machine also has excellent speed, which means it can complete a large project in a relatively short time.

The Automatic Edge Banding Machine also saves on labor costs. Sourcing labor for woodworking projects can be expensive, but with the machine, you only need one operator to handle the task. This means that you can use the saved costs to invest in other areas of your business. Additionally, the machine is easy to operate, and it comes with a manual, making it easier for any operator to use.

Types of Automatic Edge Banding Machine

There are a variety of Automatic Edge Banding Machines available in the market today. The type of machine that you need depends on the type of project you are handling. Here are some examples;

- Manual feed edge banding machine: This type of machine is ideal for small projects that only need a few edge bands. The operator feeds and guides the material through the machine manually.

- Semi-automatic edge banding machine: This type of machine is ideal for medium to large projects. It has an automatic gluing and feeding function, and the operator guides the material through the machine manually.

- Fully automatic edge banding machine: This type of machine is ideal for large-scale projects. It has automatic feeding, gluing, cutting, and trimming functions. The operator loads the material onto the machine, and the machine takes care of the rest.

If you are a woodworker, investing in an Automatic Edge Banding Machine is an excellent choice for your business. It saves you time, effort, and labor costs, which ultimately translates to significant savings in the long run. Additionally, the machine offers superior quality finishes and is easy to operate.